Research – metrology, a science in perpetual motion

Measures such as the meter, the kilogram, the second, the ampere, the kelvin, the mole and the candela are all units that were defined by the International System of Units (SI) from the end of the 18th century and were at that time based on physical items. The value of a kilo had been represented since 1889 by a standard forged from an alloy of platinum and iridium.

Over time, these physical standards were replaced by fundamental mathematical constants to ensure their reliability, especially when researching infinitely small particles for example (such as nanoparticles).

These developments were a real revolution for metrology in its continuous search for consistency.

This is precisely why Trescal has forged close ties with major European projects such as the European Metrology Program for Innovation and Research (EMPIR) and partnerships with national laboratories such as the Danish National Institute of Metrology for which it is the national reference national laboratory for alternating current/radiofrequency.

In addition to this support for research, Trescal invests 12.5 million euros each year into developing its laboratories, its standards and its technical means and into implementing new technical and IT processes.

Trescal innovations

In order to remain at the forefront in terms of expertise and to give its clients and partners added value, Trescal is in a permanent process for innovation whether it be by finding innovative methodologies or by designing new, more efficient tools.

This innovation department is divided into different areas and is supported by the Group Technical Department.

STANDARDISATION

Trescal contributes to the development of the metrology standards in force by actively participating in working groups and to the development of innovative tools for implementing these standards.

Examples :

ASSETS MANAGEMENT

Trescal is developing methodologies and tools to optimize the calibration equipment and process management.

Examples :

- Implementation and management of the Trescal Master Library database to make processing client requests easier.

- Development of the OiCM methodology (“Optimisation of metrological confirmation intervals”).

- Creation of ADVESO, measurement asset management software

- Support for implementing ISO 10012.

AUTOMATION

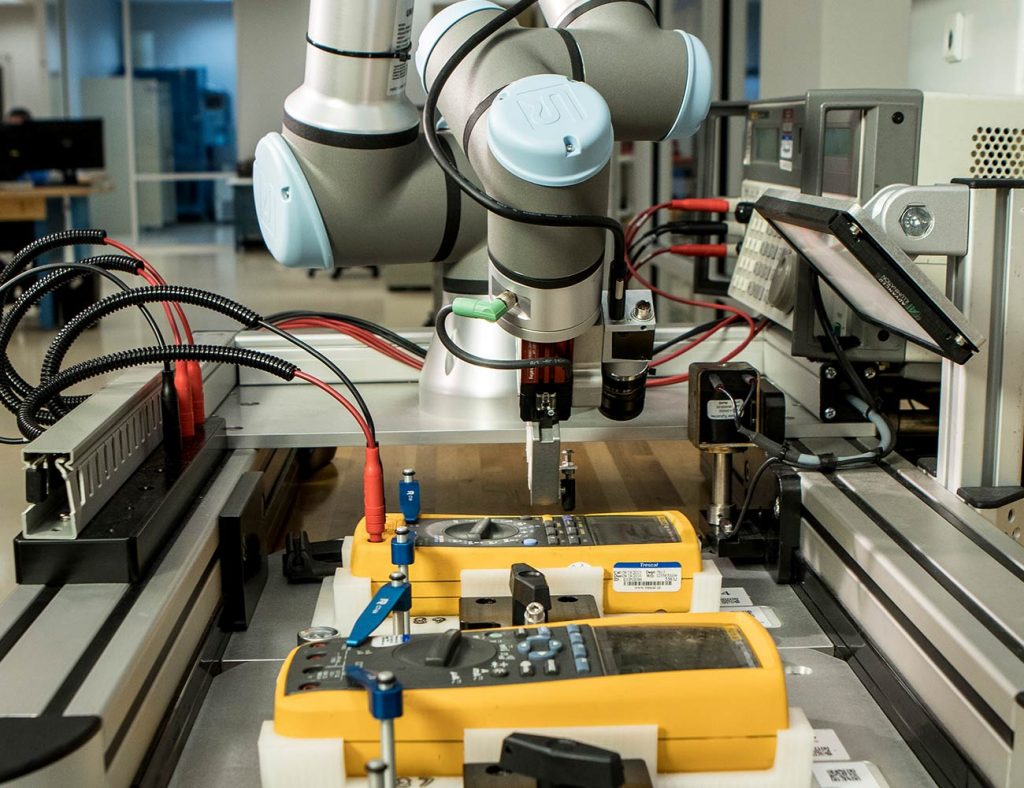

Trescal is developing systems for its own needs to automate calibration operations.

Examples :

- “Trescal Lab Manager” asset management and calibration assistance software.

- Development of test strips and special robots.

- Adaptation of third-party software (METCAL®).

Trescal is also behind product innovations, such as the Gauge Block robot or the DMM robot – which you will be able to watch via our Virtual Lab very soon on this website. Trescal has also designed portable multimeters to make daily work easier and to satisfy its clients even more.

The diversity of the laboratories belonging to the Group provides unprecedented inventiveness in the work organisation and process management which means other Trescal laboratories and the clients with whom we work get to benefit from new and innovative working methods.